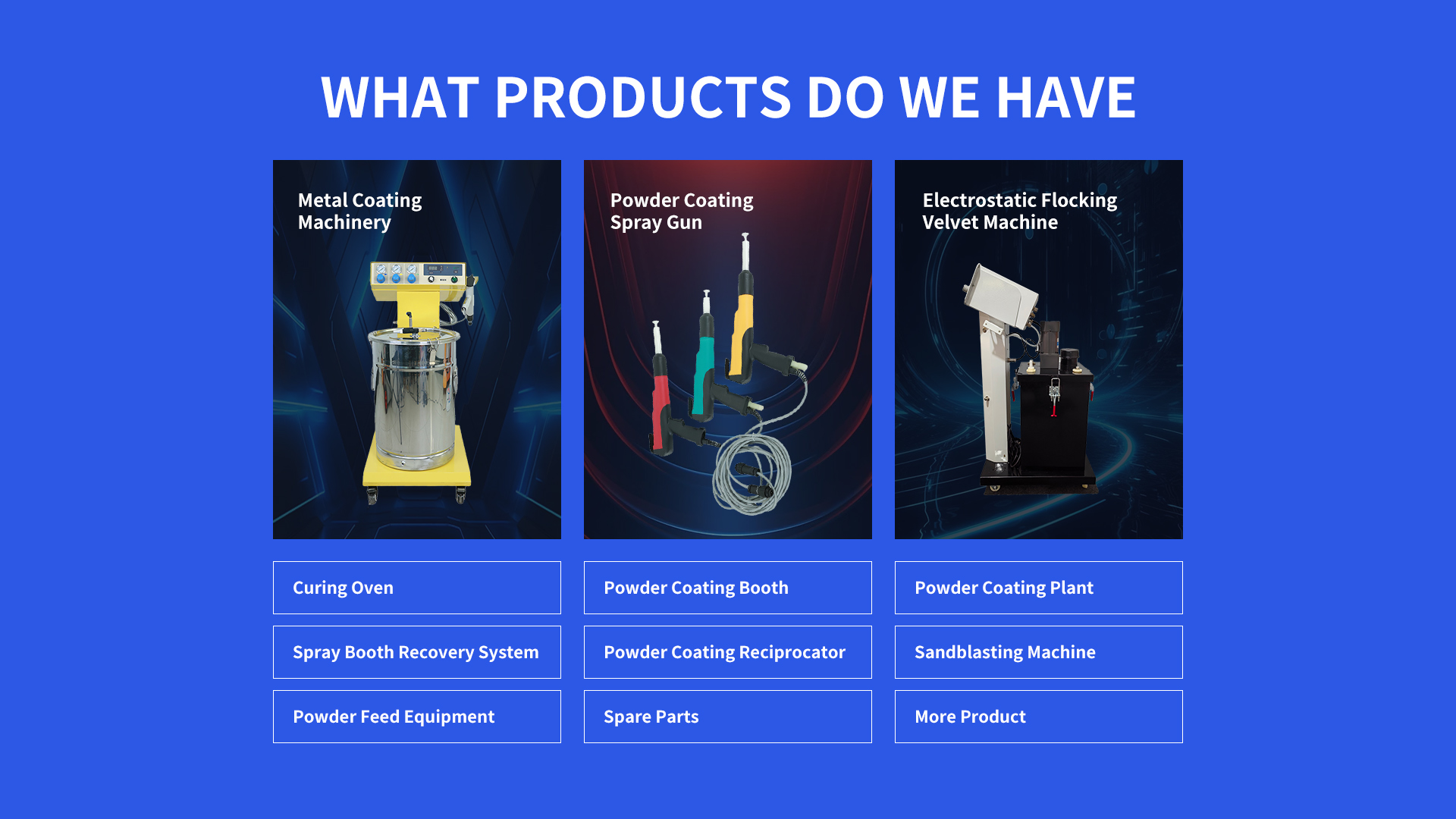

1. What is a Powder Coating Machine

A Powder Coating Machine applies dry powder to surfaces using electrostatic charge or fluidized bed technology. Key components include a spray gun, powder hopper, recovery system, and control panel. Industrial models may feature automated conveyors, curing ovens, and advanced airflow controls for high-efficiency operations.

2. Applications of Powder Coating Machines

These Powder Coating Machines are used in automotive (car parts, wheels), furniture (metal frames), appliances (refrigerators, ovens), and industrial equipment. They provide durable, eco-friendly coatings with zero VOC emissions, making them ideal for sustainable manufacturing.

3. Powder Coating Machine Price Range

Prices vary from 2,000formanualsystemsto200,000+ for fully automated lines. Factors affecting cost include size, automation level, voltage range (e.g., 50-100 kV), and features like IoT integration or energy-efficient recovery systems.

4. How to Use a Powder Coating Machine Correctly

Operators must wear PPE (respirators, gloves), ground the workpiece, and maintain a 6-12 inch spray distance. Adjust voltage settings (30-90 kV) based on powder type and object size. Clean the gun nozzle and filters regularly to ensure consistent coating quality.

5. Tips for Choosing a Powder Coating Machine

Assess production needs: Manual for low volume; automated for high volume.

Check voltage range: 50-100 kV offers versatility for various materials.

Evaluate recovery efficiency: Systems with 95%+ efficiency reduce waste.

Verify safety certifications: Ensure NFPA or OSHA compliance.

Compare warranties: Choose suppliers offering 2+ years of support.

6. Safety Tips for Powder Coating Machines

Avoid flammable materials to prevent explosions. Ensure proper ventilation to minimize inhalation risks. Regularly inspect high-voltage cables and grounding systems. Train staff on emergency protocols and PPE usage.

7. Design and Efficiency of Powder Coating Machines

Efficient machines achieve 95%+ powder transfer efficiency, reducing material costs. Modular designs allow easy upgrades, while stainless steel components enhance durability. Energy-efficient models lower operational costs and support sustainability.

8. FAQs About Powder Coating Machines

Q: What industries use automotive powder coating machines?

A: Automotive manufacturers use them for coating car frames, wheels, and engine parts.

Q: How to maintain a powder recovery system?

A: Clean filters weekly and inspect ducts monthly to prevent clogging.

Q: Are benchtop powder coating machines effective?

A: Yes, they are ideal for small workshops coating tools or prototypes.

Q: Can these machines coat non-metallic surfaces?

A: Yes, with proper pretreatment, they coat plastics and ceramics.

Q: What certifications ensure machine safety?

A: Look for CE, UL, or NFPA 33 compliance for fire and electrical safety.

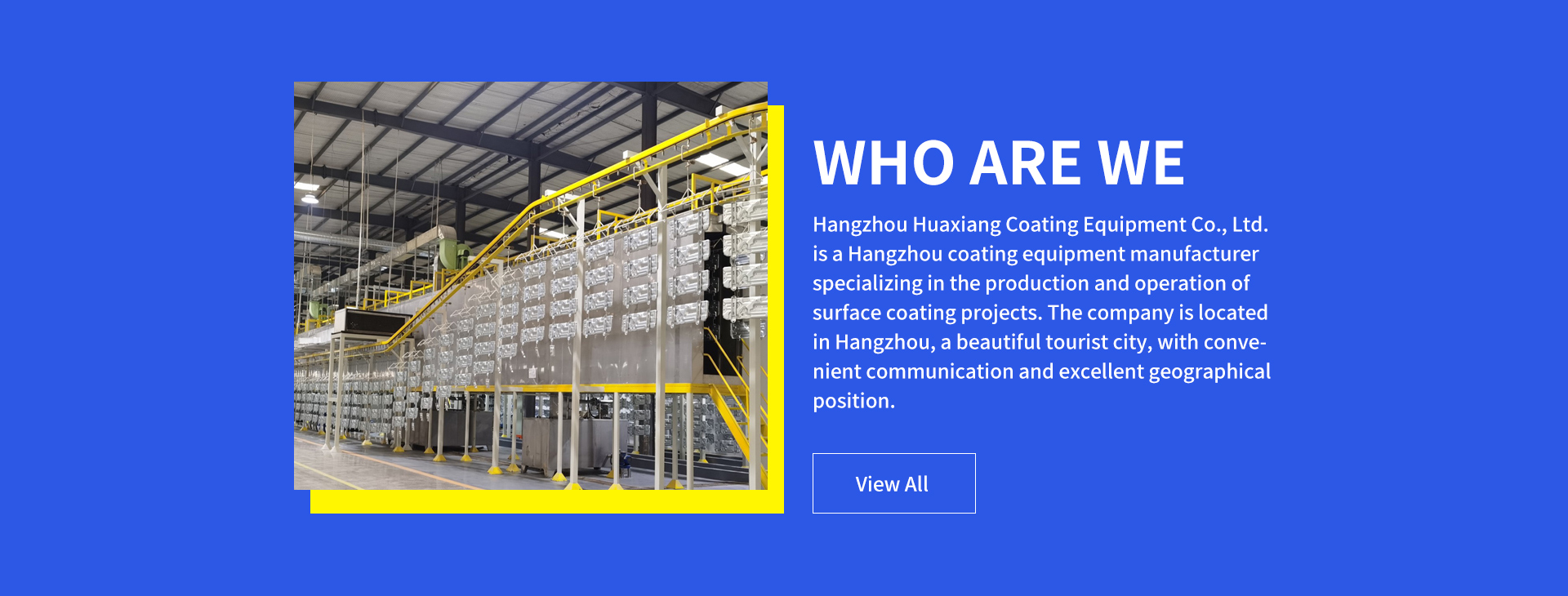

Disclaimer: Enhance your coating process with advanced electrostatic powder coating machines, precision powder coating spray guns, comprehensive powder coating systems, and efficient powder coating lines from Hangzhou Huaxiang Coating Equipment Co., Ltd. Designed for reliability and high-quality finishes, our solutions meet all your industrial powder coating machine needs. Contact us at sale3@cncolourspray.com